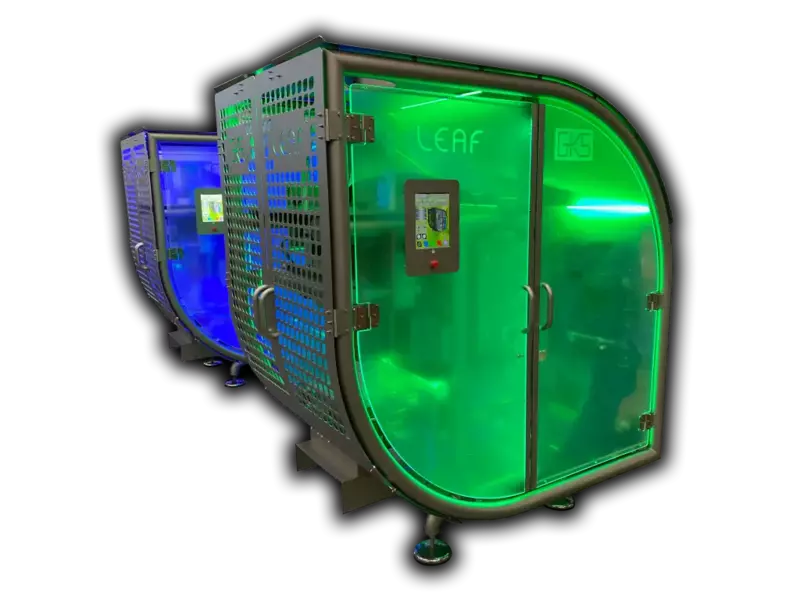

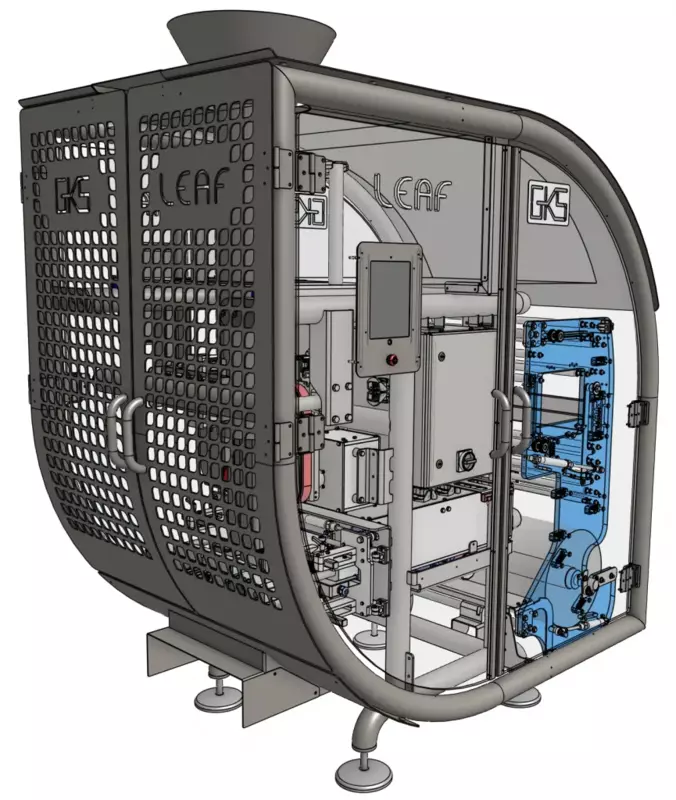

LEAF is specifically developed to produce paper bags out of 100% recyclable and compostable paper mono material. LEAF has a revolutionary design and is constructed out of stainless steel and other recyclable materials. LEAF is partly built out of recycled OCEAN PLASTIC, thus helping to reduce plastic waste. Together with the open construction for optimized accessibility, it makes the machine very easy to clean and maintain.

| LEAF | |

|---|---|

| Bag width (pillow) | 190 - 400 mm |

| Max. bag length | Unlimited mm |

| Max. bag length per sealing step | 480 mm |

| Max. production speed | 25 bags/min. |

| Film thickness | 25 - 150 µ |

| Core diameter | 76 mm (3") |

| Max. film width | 840 mm |

| Max. outer diameter film roll | 600 mm |

| Voltage | 400 V, 50/60 Hz, 16A |

| Power during production | 2500 Watt |

| Air consumption | 8 bar, 500 l/min |

All dimensions and specifications are indications based on standard set up. Final details depend on customer specifications.

We're always happy to advise you or help you find the most efficient and affordable solution to your packaging challenges. Get in touch today - without obligations - to ask any questions you may have!