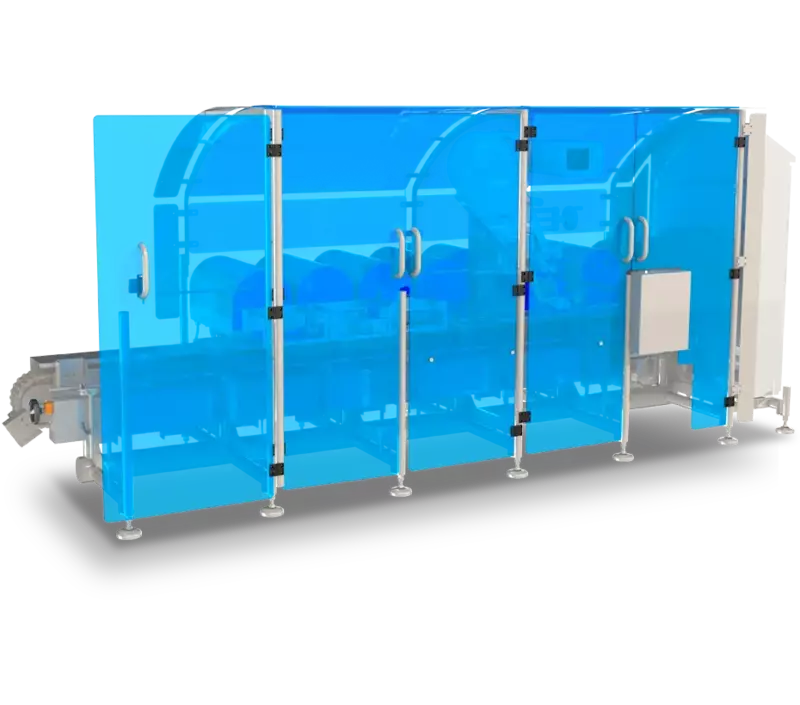

BRIC is specifically developed to shape, fold and label all common brick shapes on a vertical form, fill and seal machine with granular product. After the bag is dropped from the vffs-machine, its bottom is sealed flat, it is compressed and the air is expelled. Subsequently the top is cut and sealed. Finally the bag is folded once or twice and a closing label is applied.

| BRIC | |

|---|---|

| Bag dimensions (footprint) | 40x80 - 100x200 mm |

| Bag length | 100-250 mm |

| Max. production speed | 50-60 bags/min. |

| Voltage | 400 V, 50/60 Hz, 32A |

| Power during production | 2000 watt. |

| Air consumption | 1500 l/min |

| Air pressure | 8 bar |

All dimensions and specifications are indications based on standard set up. Final details depend on customer specifications.

We're always happy to advise you or help you find the most efficient and affordable solution to your packaging challenges. Get in touch today - without obligations - to ask any questions you may have!