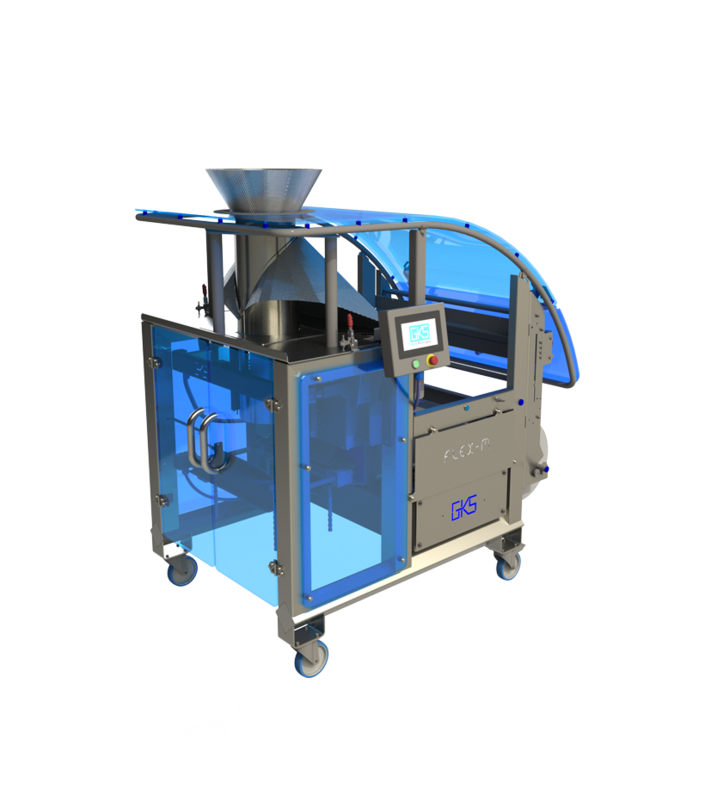

The FLEX-M is suitable for packing a wide variety of food and non-food products. They work seamlessly with a variety of weighing and dosing systems, and are also very suitable for manual filling. The stainless steel machines are designed with reliability, flexibility and hygiene in mind. Thanks to their open construction, they are extremely easy to clean. Low height coupled with a small footprint makes FLEX-M very versatile in small production areas as well as industrial environments. Modules can be exchanged within minutes, maximizing usability whilst lowering downtime and cost. Machines can be configured in line with customer requirements on request.

| FLEX-M | |

|---|---|

| Bag width (pillow) | 75 - 350 mm |

| Max. bag length | Unlimited mm |

| Max. bag length per sealing step | 230 mm |

| Max. bag length per sealing step extended version | 330 mm |

| Max. production speed | 40 bags/min |

| Film thickness | 25 - 120 µ |

| Core diameter | 76 mm (3") |

| Max. film width | 750 mm |

| Max. outer diameter film roll | 320 mm |

| Voltage | 230 V, 50/60 Hz |

| Power during production | 1,200 Watt |

| Air consumption | 6 bar, 150 l/min |

All dimensions and specifications are indications based on standard set up. Final details depend on customer specifications.

We're always happy to advise you or help you find the most efficient and affordable solution to your packaging challenges. Get in touch today - without obligations - to ask any questions you may have!